Ergonomics aims to make sure that tasks, equipment, information and the environment suit each worker.

It is a field of study that has contributed to the understanding of work-related stresses and solutions, anatomy and physiology, anthropometrics, biomechanics, psychology, and industrial design and engineering. Industrial Engineering Terminology (revised edition, 1991), defines ergonomics as: “The application of a body of knowledge (life sciences, physical science, engineering, etc.) dealing with the interactions between man and the total working environment, such as atmosphere, heat, light and sound, as well as all tools and equipment of the workplace.” It is indeed a highly interdisciplinary field which helps the worker to attain higher productivity due to less fatigue, safer working environment (fewer accidents), lesser absenteeism and reduced labour turnover.

Why Ergonomics?

Ergonomics aims to make sure that tasks, equipment, information and the environment suit each worker. It is a field of study that has contributed to the understanding of work-related stresses and solutions, anatomy and physiology, anthropometrics, biomechanics, psychology, and industrial design and engineering. Industrial Engineering Terminology (revised edition, 1991), defines ergonomics as: “The application of a body of knowledge (life sciences, physical science, engineering, etc.) dealing with the interactions between man and the total working environment, such as atmosphere, heat, light and sound, as well as all tools and equipment of the workplace.” It is indeed a highly interdisciplinary field which helps the worker to attain higher productivity due to less fatigue, safer working environment (fewer accidents), lesser absenteeism and reduced labour turnover.

‘Is the job fit for the worker and is the worker fit for the job’? – Sir Thomas Legge, Britain’s first Chief Medical Inspector of Factories

Are as of ergonomic intervention include the human-machine interface, environment, hardware and work posture. Some of the factors that affect ergonomic interests are: Climate (Temperature, Humidity and Airflow – Ventilation); Noise, Illumination, Vibration and Radiation; besides Work Time/Shift, Work Overload, Ageing, Material Handling, Stress or Strain and Load.

Human-machine interface

The human-machine interface involves Displays, Text Clarity and Controls.

Display must be as clear and as easy to read as possible. The display must meet the needs of the human beings operating the machine or the equipment. Text clarity should be on KISS (Keep It Short and Simple) principle; and the readability should be as per Gunning Fog Index. Control factors to be accounted for are: Speed – For example, the reverse stitch switch in a programmable lockstitch machine is located close to needle point for footer response. If fast response is required, then operation will be done by hand or fingers; Force – It should be well-balanced; excessive force should be avoided and an amount of certain force is necessary to prevent a control from being accidentally tripped; Grouping – Depending on the frequency of use, buttons or switches with similar functions should be grouped together; Accuracy – Which can be like in the form of using a mouse to select icons on a screen; Illumination – Colour codes, shapes and textures should be clearly legible, having clear visibility from wide angle and with the right intensity of illumination; Population stereotypes – The routine activities should conform to the prevailing convention, like sewing machine flywheel turning anti-clockwise; a valve turning clockwise which means ‘close’; red which means ‘stop’ (danger); green which means ‘go’ (safe to go); yellow line which means ‘machine working limit’, are some of the examples.

Environment

Environment includes workplace layout, automation and manufacturing systems.

Workplace Layout

The tendency of operators to work in the hunched posture also suggests a potential conflict between workstation geometry and operator dimension. Analyses indicate that most commonly operators position the chair away from the work surface in order to allow a knee angle of 110 degrees or greater. Factors limiting operator access to the workstation are the location of the treadle which is too close to the proximal edge and various other obstructions (motors, pneumatic equipment and machine guards) beneath the table. While typical recommends knee room averages of about 46 cm, the presence of these obstructions, in some cases, limits available space to less than 26 cm. In consensus with the ergonomist’s recommendation, numerous operators express a strong preference for positions in which the rear of the workstation is tilted upwards.

Automation

Automation, for example, can reduce the skill requirements of a complex positioning and guiding task and also eliminate many high-risk hand and wrist postures and the frequency of hand movements, thereby reducing the exposure to common repetitive trauma disorders.

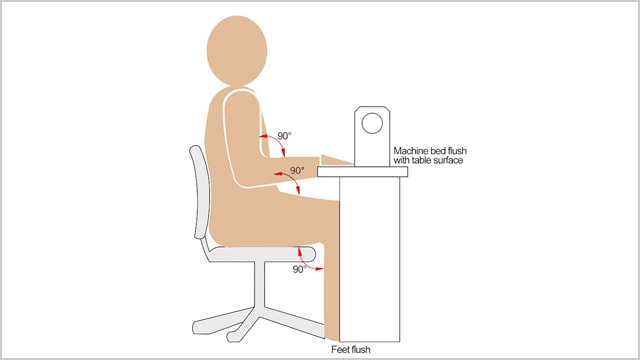

Right combination of stool and table height is essential for correct posture. Operators typically adopt hunched posture resulting in discomfort in the back and neck.

Manufacturing Systems

Notable success in attempts to introduce modular manufacturing are found in reducing repetitive strain injuries. Anecdotal reports suggest that, after a period of adjustment, many workers experience significantly decreased levels of musculoskeletal discomfort due to the increased variety in movements and improved postures at the standing workstations and the motivational factors. Increased morale and workgroup cohesiveness, along with substantially reduced absenteeism, have also been seen in successful implementations.

Hardware

Hardware includes tools and seating. The vast majority of operations are performed in a seated position. Seating encountered in the sewing environment typically consists of straight-backed wooden or metal chairs. In most places, the provided chairs lack any cushion for reducing compression and fatigue, lack adjustable backrest, and often are of improper height. Most operators (91%) customize their chairs with homemade cushions on the pan and backrest in order to adjust the height and increase pliancy. Most cushion adjustments increased seat height by 3-6 cm when compressed. In a study, the workers reported almost 90% reduction in discomfort frequency when using the ergonomically-designed chairs.

Right combination of stool and table height is essential for correct posture. The height of adjustable sewing table stands ranges from 70-80 cm and stool height used in Indian garment industry ranges from 45-48 cm. The indicative anthropometric data (based on a pilot study done by GMT department in NCR) of sewing workers, suggests that only 50% of the workers are comfortable with existing machine height and 32% of workers are happy with existing stool height. Customizing table and stool height combination shows improvement of performance and reduction of SAM value by 4-12%.

Use of attachments, work-aids and tools

The production of a ‘felled seam’, the kind of double overlapped seam found on the side of denim jeans, requires an awkward posture of wrists, hands and fingers to evenly guide the fabric through the folder. An automated felled seamer (senses the fabric edge inside the folder) simplifies the job even further, allowing the operator to use nearly neutral wrist and hand postures throughout the operation. A puller feed reduces the force operator needed to exert in many operations, like elastic attach, waistband attach, jeans inseam, etc. Use of binders and hemmers reduces finger manipulation job of an operator in many operations like hemming, neck binding, pintucking, etc. Even a pair of ergonomically-designed scissors will benefit workers.

Work posture: Improvement through training

Much of the reported discomfort in the back and neck can be attributed to the working posture of the seated operators. In response to job and workstation characteristics, operators typically adopt a hunched working posture. Several workers stated that this posture is necessary to obtain maximum production and wages. Such postures have been cited as a factor in muscle fatigue and discomfort. The tendency of operators to work in this hunched posture can be attributed to at least three factors: the visual demands of the work, the geometry of the workstation and inadequate seating, which can be corrected by using right equipment.

But substantial improvement in both posture and frequency of musculoskeletal discomfort can also be achieved by proper training and awareness about right posture. For example, a mean improvement of back angle by 9 degrees among workers decreases musculoskeletal pain by 90.3%. Moreover no change in production is noticed. Posture is constrained by both the visual and manual aspects of the task and the design of the sewing machine and table have a considerable influence on the posture adopted. The potential for improvement of industrial sewing machines was investigated and a study of the effects of two design parameters was made (table inclination and view of the needle).

The study indicated that both trunk posture and head/neck flexion could be improved significantly by altering their design parameters. Trunk posture was found to be strongly related to the manual aspects of the task, and could be improved by altering the working positions for the arm. Head posture was most influenced by the view of the task/needle and could be improved by enhancing the visual condition for the task.

Occupational hazards

A study has found that finishing workers in the clothing industry may be exposed to stain removing chemicals, thus subject to hydrazine compound induced contact eczema. Industrial sewing work involves a pattern of shoulder muscle activity which induces fatiguing processes in the shoulder and neck regions. Furthermore, since the static shoulder muscle load was independent of muscle strength, i.e. shoulder does not make any movement during sewing but the muscles are loaded due to the movement at elbow-wrist-finger, factors other than working posture may be of significance for the static muscle load. Further, the babies whose parents worked in the clothing industry were significantly smaller for gestational age than were babies of other manual workers.

According to international benchmark standard, nearly 60-95% of operations of common product categories (like shirt, trouser, jogging suite, etc.) are repetitive in nature. A significant relationship exists between hand pain and repetition rates. There are on an average 29 left-hand and 25 right-hand posture changes per cycle. High degrees of manual manipulation are associated with higher levels of physical discomfort almost throughout the body. Greatest discomfort levels are concentrated in the neck, upper and middle back, right shoulder and hands. A survey among sewing workers in NCR during the year 2000 revealed that nearly 80% of them had low back problem while 62% had shoulder pain.

Factors Affecting Ergonomic Interests

Climate

Physiological demands are placed on an operator through the performance of a given job or task, the thermal environment (temperature and humidity) and the rate at which muscular fatigue develops. Build-up of fatigue means increasing the risk of accidents and injuries and also can distract operators from the task at hand. While basic metabolism rate is 1.0 Kcals/min, different body positions and movements require different calories. While sitting requires 0.3 Kcal/min, standing and walking require 0.6 and 3.0 Kcals/min, respectively. Type of work also decides calorie requirement. Sewing requires 1.0 to 3.5 Kcals/min, CAD operator requires 0.2 to 1.2 Kcals/min, while loading workers at finished goods warehouse requires approximately 7.0 Kcals/min.

Illumination

Most sewing operations are visually demanding, requiring the precise stitching of thread into a fabric with which there is little or no visual contrast. Hunched working posture is also in order to see their work. Illuminating Engineering Society of North America (IESNA) recommends a value of 300 fc (foot candle) for visually intensive tasks with low contrast at the point of operation (POO). A pilot study conducted in the year 2000 among garment sewing workers, reveals that 45% of them faced pain in eyes. The best way to minimize the eye pain and reduce posture related injuries is to use needle lights.

The ageing worker will need an ergonomically-friendly environment in order to do a quality job.

Vibration and Radiation

Vibration causes visual damage like blurring of subjects, resulting in undue strain on eyes. It also causes motion performance effects. If vibration frequency is above 20 Hz, it leads to nervous system disorder, if it 20 Hz – then spinal problems are detected and at less than 20 Hz, digestive complain happens. Machines with highest leakage of radio frequency electromagnetic fields were found in the readymade clothing industry in plastic welding operation for carton strapping.

Work time/shift

To result in optimum performance, the human circadian rhythm (8 hour work, 8 hour free time, 8 hour sleep) should be considered as normal. A sufficient number and length of breaks should be given. Recognized shift-work programmes should be utilized (day- and night-shift alternating). Optimal temperature to work is 98.60 F ± 1.80 F (370 ± 10 C), which is the human core temperature. Rising of the core temperature means the worker will suffer from a heat disorder (heat stroke, heat exhaustion). If the heat and humidity levels rise above the comfort zone, energy is mainly diverted toward keeping the body cool.

Material handling

Unlike in conventional manufacturing operations, where unfinished garments are carried, dragged, or wheeled on specially-designed carts between workstations, a computer-controlled overhead conveyor (UPS) may be used to move partially assembled garments from one workstation to the next. The UPS reduces horizontal reach requirements and eliminates heavy lifting by the operators. It resulted, however, in increased vertical reach requirements and increased wrist pronation during acquisition of materials. A survey among UPS users indicated slightly higher frequencies of hand and leg discomfort than among their counterparts who utilized conventional materials handling. Also some operators complained about a perceived increase in the noise level (95-97dB) and reported temporary auditory threshold shifts during and after the workday.

In contrast, PBU system has problems of heavy lifting by helpers or supervisors and upper body movements (operators twisting their upper body to reach for garment bundles).

Nature of work

Static work is another situation where an unacceptable build-up of fatigue may occur. It is performed by the muscles in any activity that involves holding a position for a certain period of time. Some examples of static work are holding things with the hands (inspection), bending or leaning forward (picking up bundles by sewing operators), standing without moving or sitting in the position (thread trimming, spotting), working with the arms extended (inspection), etc. whereas some of the examples of dynamic efforts are materials handling (lifting, pulling, pushing and carrying).

Ageing

Due to ageing, the loss of motor reunions to skeletal muscle cells resulting in decreased nerve simulation contribute to the cause of muscle atrophy, the decrease in the number of neurons and decrease in muscle fibre area, reducing the size of individual motor units in the skeletal muscle. Thus, an increased number of motor units must be activated in order to exert force on a body of mass. For this reason, exerting force on an object requires increased effort from the elderly and also results in lack of fine coordination. Body weight increases till 50-59 and then starts reducing. Body stature also changes with age; it decreases 30-39 onwards at a rate of 1.2 cm/decade.

As workers start aging, their biological and psychological capacities change thereby affecting their performance abilities. Environmental design can compensate for declines in functional capacities and take advantage of the experience and wisdom of older workers to permit ideal productivity. “In general, they have fewer accidents, declining absences, and equal or higher productivity than the younger workers. The elderlies possess better judgement, reduced risk, caution and stability and of course company loyalty.

Conclusion

Keeping in mind the different social responsibility structures and population growth in India, whether the same stringent occupational health and safety standards of developing countries can be applicable in India even in distant future, is a million-dollar question. If not for the sake of compensation or due to buyer’s compliance parameter, but for other intangible business benefits, occupational health and safety parameters should be taken seriously by Indian manufacturers. A high labour turnover rate (well over 100% annually in many plants!) contributes to escalating training costs. On a typical job, novice operators require 12-16 weeks of training and practice before their performance reaches established production standards. On especially difficult jobs, as long as 26 weeks may be needed. For most workers, learning curves do not reach asymptote until after one to two years on the job. Health and safety should not just be reactive (i.e. training staff to deal with accidents and reducing hazards), but proactive to clearly identify potential hazards before incidents occur.