Moving forward from its initial use on warm blankets, quilting has found its way into newer and broader product categories involving wall hangings, table cloths, covering for couches, handbags and apparels. This extended scope of quilted products is also the reason for the manufacturers as well as designers of quilted goods to gain bigger market space. Another reason that has added on to the growth of the quilting industry is the fact that the equipments and machines used for making these products have undergone massive improvements making it possible for manufacturers to supply high-quality products in much less time.

Team StitchWorld with Ramita Bali, MF Tech from NIFT, Delhi, discusses different levels of technology solutions available for a quilting operation, the makes and models of machine and equipments available in the market and also the return on investment on the basic and highest levels of technology.

Quilting involves sewing through three layers of material, namely the top fabric layer usually of cotton or polyester; the middle layer of batting or wadding in felt, wrap or a roll form usually of cotton, polyester or wool fibres; and finally the backing which is the bottom fabric layer. All the three layers are placed one above the other to form a quilt sandwich, which is then basted together to hold them securely for better and accurate quilting.

There are many options available for quilting, from very basic stitching technology to advanced computerized versions. Each version has its advantages and while the basic technology requires hand basting, in case of automatic quilting machines, the layers to be quilted are placed on a special frame keeping the layers together without the need for basting or pinning. Each technology is suited to the needs of different companies with distinct requirements.

Basic Level of Technology Single Needle Lockstitch Machine with Long Arm Bed

The introduction of single needle lockstitch machine with long arm bed revolutionized the whole process of quilting as it replaced the earlier cumbersome method of hand quilting. The operator places the quilt sandwiched under the pressure foot, and starts quilting from the centre in an outward direction to avoid any gathering of layers, ensuring a neat product. Though the long arm helps in accommodating larger pieces, it requires constant manoeuvring by the operator while stitching. The machine comes with a quilting guide and a drop feed. The operator moves the fabric as per the design to obtain quilting.

An auxiliary table is provided as standard to extend the work area to 23 inches and allow for even larger pieces to be quilted with ease.

Usually the sewing speed is 1500 SPM, producing a stitch of 6 mm length. Pfaff 1222E, Keestar GSC8BL20 and Juki TL98Q are among best examples of a single needle lockstitch machine with long arm bed.

Intermediate level Single-head quilting machine and cam controlled multi needle quilting machines

Single-head quilting machine

Though the advent of single needle sewing machines has revolutionized the process of quilting, most of the operations are still being done by an operator and thus output is dependent on the efficiency of the sewing operator. The method of basting the layers before quilting continues to remain very time consuming, while the working area on a long arm bed is not enough to manage the bigger pieces of cloth meant for quilting bed spreads or wall hangings etc.

To deal with this limitation, machine manufacturers introduced single head single needle lockstitch quilting machine with a bigger sewing area and the major difference in sewing method was that instead of fabric movement, now it is the sewing head which moves all over the fabric placed on a frame, eliminating the need of basting the layers. This change not only removed the problem of material handling but also increased the productivity of the machine.

The machine has an in-built touch screen colour LCD monitor usually ranging between 10-10.5 inches in width, in which the required design is stored and selected by the operator before quilting. The monitor also displays information such as current status of the needle as per the design, stitch numbers, coordinated values determining accuracy of needle point and most importantly the machine comes with an in-built memory to store patterns for future use. Achieving a high level of automation, the system can automatically detect thread breakage to avoid any discrepancy in the design, alerting the operator to re-thread the machine.

The operator can also edit the pattern with the input functions displayed on the screen such as resizing the design. Option of a test run or floating the design is also available, in which the pantograph of the design actually moves without sewing, giving a fair idea of the look of the garment after quilting. A pantograph is a technique used for tracing an image by the software.

Won Chang Wqm-3000 by Quiltex India is one of the best examples of such a technology. It can stitch up to 3000 stitches per minute and can accommodate a frame with dimension of 2.3 x 2.6 metres to accommodate larger patterns. These frames are flexible in nature and can be reduced or increased in size as per the design requirement. The customer also has an option of customizing the working area of a machine as per his requirement.

Shuttleless multi needle quilting machine

Prevalently used for mattress quilting, Shuttleless multi needle quilting machines have a huge market and are preferred by many quilt suppliers over other options. The machine produces a chainstitch instead of a lockstitch as compared to other quilting machines. It is based on a double lock chainstitch technology, which means double chainstitch is formed using two threads ensuring stronger seam.

The machine can quilt at maximum sewing speed of 1200 SPM (stitch per minute) and is capable of producing intricate patterns with automatic cutting of top thread. Installed with a touch screen LCD monitor of 10.4 inches, all the information regarding the design, current status of the operation and stitch number are well displayed. Similar to the structure of computerized multi needle quilting machines, these machines have two rows (at 3 inch distance from one another) comprising of 94 needles each, placed at a distance of 1 inch from each other, supported with 94 loopers, which provides the second thread in the stitch. The machine is also equipped with a top fabric tray feeding device with adjustable brake which provides a constant and accurate top fabric tension control to any kind of fabric.

Even with so many advantages, the machine is restricted to only mattress and blanket quilting for its threads have an unravelling property not suited to the wear and tear associated with garments.

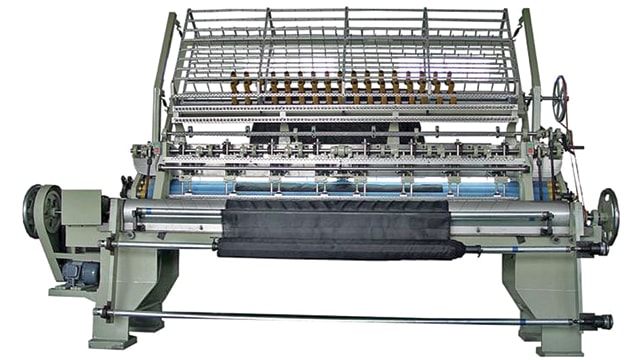

Cam-controlled multi needle quilting machine

In order to meet the market demand of faster delivery, cam-driven quilting machines were launched with multi needles. These machines are now widely used in the industry and can also be customized as per the cam specifications of the client. After loading the frame and selecting the pattern, the machine quilts automatically, without any help from the operator. Due to the presence of dot presser system, there is reduced resistance on presser-plate when quilting extremely thick materials.

The customer can choose from various machine models with variable speed, number of needles and shuttles. Such machines have 2 bars or needle rows, with a gap of 3 inch between them; each row comprising of certain number of needles, varying from 64 to 118, placed at a distance of 1 inch from each other. Consequently, the working width of such machine varies from 64 inch to 118 inch. For the formation of a lockstitch, lower thread is supplied with the help of shuttles fitted in shuttle holders. Each shuttle has a needle, hence between the 2 bars the number of shuttles vary from 128 to 236 for these machines. The speed of such machines can go up to 500 RPM.

KW64A by Won Chang and HA-66E/B by Fanya are some of the examples of cam type multi needle quilting machines. Won Chong is available in India through Quiltex (India) Pvt. Ltd. and Fanya through Sterling Creations Pvt. Ltd.

Advanced Level: Computerized multi needle quilting machine

Computerized quilting machines are among the most advanced quilting machines in the world. Through its new feature of jump and tack facility, the machine in case of a thread breakage or machine stoppage, starts sewing from the same point where it stopped by jumping back a stitch and tacking it again. The process helps in executing the design with perfection and reducing the need for mending any broken or misplaced stitch in the design. With the help of the touch screen LCD monitor, the operator can easily edit and save patterns.

Looking at the changing fashion needs, the manufacturers have designed the machine in such a way so that even intricate patterns such as flowers or other objects with 360 degree curve can easily be quilted with precision, eliminating the drawback of cam-driven machines. In addition to all the features available in cam-driven quilting machines, computerized machines are equipped with a unique adjustable (0~40 mm) active roll feeding system which can adjust materials of different thickness and allow sewing without skip stitches on both very thick and very thin materials and exotic “puff” effects without destroying materials. The touch screen panel has an added feature of error detection, signalling the ‘sign’ until the problem such as broken thread, is solved. The machine can be used to quilt apparels, bed spreads and wall hangings with ease.

Based on working width, the number of needles and speed, there are various computerized quilting machine models available to choose from. Similar to the structure of cam type quilting machines, these machines have two rows (at 3 inch distance from one another) comprising of 64 to 130 needles each, placed at a distance of 1 inch from each other. Consequently, the working width of such machine varies from 64 inch to 130 inch and the number of shuttles varies from 128 to 260. All the models come with a LCD computer panel, and stores up to 280 designs. The speed of the machines can go up to 600 RPM.

The HA-66C/A by Fanya and KW64C by Won Chang are some of the best computerized multi needle quilting machines available in the market.

Working formulas

• Finishing cost = 0.20 x CM of the garment

• CM price per Operation = Finishing cost x (SAM for single operation/Total SAM)

• Production per day (shift of 8 hours) = 480/SAM value for single operation (min)

• Production per annum = Production per day x Working days per in month x No. of months per year

• Cost output/annum = Production per annum x CM price per garment inspected

• No. of machines required = Roundup (Production Target/Production per day, 0)

• Cost of total machine (Rs.), T = No. of machines required x Cost of one machine

• Depreciated value of machine after one year (Z) = Cost of total machine x [1 – Annual Depreciation (%)]

• Total operators salary (Y) @ 12 months = Cost of one operator per month x No. of operators x 12

• CM price from total machine (X) = Cost output per annum x No. of machines required

• Total kWh consumption = kWh consumption of one day (8 hour) x 26 x 12 x No. of machines; 1 kWh = 1 unit

• Total electricity consumption (W) = Total No. of units x 5 (price of one unit)

• Cash Inflow (I) = X – Y

• ROI for the first year = (X-Y-W)/Z = I/Z\

• Payback Period = T/I

ROI for technology in Fabric inspection |

||

| Quilting | ||

| CM price of a jacket (Rs.) assumed | 400 | |

| Quilting cost (40% of Rs. 400) | 160 | |

| SAM value for quilting a jacket (min.) | 29 | |

| CM price per operation (Rs.) | 160 | |

| Intermediate Level of Technology | Advanced Level of Technology | |

| SAM value for quilting a jacket (min.) | 29.00 | 3.50 |

| Production per day (shift of 8 hours) | 16.55 | 137.14 |

| Working days in a month | 26.00 | 26.00 |

| Months in a year | 12.00 | 12.00 |

| Production per annum (pieces) | 5,164.14 | 42,788.57 |

| CM price per garment quilted (Rs.) | 160.00 | 160.00 |

| Cost output per annum (Rs.) | 826,262.07 | 6,846,171.43 |

| Production target (pieces per day) | 1,000.00 | 1,000.00 |

| No. of machine required | 60.42 | 7.29 |

| Cost of one machine (Rs.) | 300,000.00 | 2,400,000.00 |

| Cost of total machine (Rs.) (T) | 18,125,000.00 | 17,500,000.00 |

| Annual depreciation (%) | 15.00 | 15.00 |

| Depreciated value of m/c after one year (Z) | 15,406,250.00 | 14,875,000.00 |

| Cost of one operator per month (minimum wage) | 5,500.00 | 4,800.00 |

| Total operators salary (Y) @ 12 months | 3,987,500.00 | 420,000.00 |

| Total KwH consumption per year | 15,682.36 | 115,814.00 |

| Electricity cost per year (Rs.) (W) | 78,411.80 | 579,070.00 |

| CM price from total machines (X) | 49,920,000.00 | 49,920,000.00 |

| Cash inflow (I = X-Y-W) (Rs.) | 45,854,088.20 | 48,920,930.00 |

| ROI for the first year (X-Y-W)/Z (%) | 297.63 | 328.88 |

| Pay back in terms of months | 4.03 | 3.65 |