A simple cotton bed sheet available at a department store might cost US $ 25 to US $ 30. But add a line of decorative stitching along the edge, and it looks like the US $ 99+ set that came out of a fancy catalog. Similarly, a decorative topstitch on a coat or a dress or an ornamented hemming at the edge of ladies top, could be a considerable source of value addition to it without struggling with beads, sequins, or other value add-on items. Stitching a nice straight seam is important, but so is the aesthetic value of the garment. For that purpose, there is an alternative in the form of decorative stitches. All an operator has to do is to just push the treadle and out comes swirls, leaves or diamonds in a row. Even though the purpose behind using decorative stitches is to add value to the garment, they also serve ulterior motives in hiding seams or mistakes… StitchWorld discusses in detail a few essential ones.

One should not confuse decorative stitches with embroidery. While some of them do look like lines of hand embroidery, in the sewing industry ’embroidery’ always refers to the stitching done by an embroidery machine, using a special carriage and hoops. The hooping system is employed to hold the fabric in place as the design is executed. Embroidery, by contrast, is primarily decorative. Decorative sewing, however, works like general sewing, by having the fabric under the sewing foot with the feed dogs feeding the fabric in the correct sequence to make the selected stitch. It typically involves joining two pieces or fabrics; finishing the edge of a single piece of fabric or manipulating the drape of a piece of fabric, as with pleats or darts.

There are a wide range of sewing machines available for decorative stitches. In general, as much is the demand of your product, more decorative stitches are included. Basic machines traditionally offer just basic stitches, like a zigzag and satin stitch. Advanced machines often include stitch packages of 20-40 decorative options. Pfaff Creative 2170, Bernina 950, Janome 712 T which can also make buttonholes, and Kansai Mac 100 are a few examples.

[bleft]There are a wide range of sewing machines available for decorative stitches. In general, as much is the demand of your product, more decorative stitches are included. Basic machines traditionally offer just basic stitches, like a zigzag and satin stitch. Advanced machines often include stitch packages of 20-40 decorative options. [/bleft]

Selection of sewing machine is not everything, choosing an appropriate thread is equally crucial for the utility and finished appearance of the stitch. Most sewing machines can be adjusted to accommodate a variety of threads. If the stitch you want to use is very complex, choose a sturdy but thin thread that is unlikely to snag. A more straight forward stitch or one that moves linearly rather than frequently changing angles can use more delicate threads. Mostly the selection of thread depends on the weight of the fabric used. The heavier the fabrics on which the decorative stitch is being applied, the higher is the ticket no. of the thread (in TEX).

Even though the most modern sewing machines offer the greatest range of decorative stitches, decorative sewing machines aren’t a rage in the market, particularly because programmable, computer-controlled machines can be far more expensive than what may be justified for the sake of a few embellishments. It is possible, however, to adjust the width, height, and span of stitches even on simpler machines to create your own variations of decorative stitches. Although there are machines which come with numerous decorative stitch options, most of them are just pre-defined variations or combinations of certain decorative stitches. Some of the most commonly used decorative stitches which are also being used to add value in a range of apparels are:

Zigzag Stitch

A zigzag stitch is variant geometry of the lockstitch. Traditionally it was a back-and-forth stitch used where a straight stitch will not suffice, such as in reinforcing buttonholes, in stitching fabrics with stretch, and in temporarily joining two work pieces edge-to-edge. But today being one of the most commonly used decorative stitch, the zigzag stitch in variation of widths is used to replace the boring running stitch to attach two fabrics or a trim to a fabric in fashion today. Commonly used on the yokes, hems, cuffs and necklines, and for patchwork, smocking, to attach a trim or as a design element, the zigzag stitch remains evergreen in fashion.

When creating a zigzag stitch, the back-and-forth motion of the sewing machine’s needle is controlled by a cam. As the cam rotates, a fingerlike follower, connected to the needle bar, rides along the cam and tracks its indentations. As the follower moves in and out, the needle bar is moved from side to side. Very old sewing machines lack this hardware and so cannot natively produce a zigzag stitch, but there are often shank-driven attachments available which enable them to do so.

This is a two/three/four step zigzag where there is 2/3/4 stitches to the left and then equal number of stitches to the right. This pattern is repeated for the length of the seam; the stitches use a single needle thread and single bobbin thread. The main application of this stitch is in attaching elastic and seaming intimate apparels. The recommended thread for this stitch is T-24 Core or T-27 Spun Poly.

The J20U53 from Japsew, KM 2070P from SunStar, 20U53 & 20U93 from Zoje and LZ-391N from Juki are some common machines for zigzag stitching.

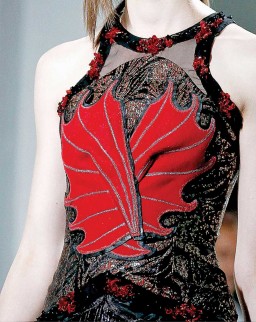

Satin Stitch

The most prominent of the fancy stitches, satin stitch is widely used as a filling stitch for filling a particular motif, or for embroidery like look.Beautifully used as a finishing stitch to cover up the edges seamlessly, the stitch is more or less utilized to conceal the seams with perfection neatly.

It is technically understood as a completely filled column of zigzag stitches achieved by setting the stitch length to 0.2 – 0.4 mm, the length setting should be short enough for complete coverage but long enough to prevent bunching and thread build-up.

Since the satin stitch is nothing more than a very short zigzag stitch, therefore most of the machines used for zigzag stitching can be adapted for satin stitch.

Blanket Stitch

Traditionally used as a finishing stitch to envelope the raw edges of the hemlines, the blanket stitch is often used to trim the sides of a blanket and hence got its name as the blanket stitch, which is now innovatively worked on as a design element, also to patch or as an applique technique, to decorate the edge of a crocheted item or to protect the edges of fabric to prevent unravelling and fraying. Stitch formation is with 4 stitches per inch with a seam width of half an inch usually. A blanket stitch is used for decorative edging on a variety of different items, usually serging edges of blankets, sweaters, polar fleece, washcloths, towels and other linens. The standard blanket stitch is created by pushing the needle through the fabric from the front, about a quarter of an inch or five millimetres from the edge of the fabric. The needle is then brought around the edge of the fabric and up through the loop of thread before the stitch is pulled tight. The stitch is then repeated by again pushing the needle through the fabric from the front side. The most appropriate thread for this stitch is T-180 to T-350 Spun Polyester.

The Merrow 18-E is an efficient sewing machine for making blanket stitch.

Overedge Stitches

Overedge stitches are used as finishing stitches for binding the unclean edges of the hem, collars, cuffs, etc. Use of fancy or contrasting thread enhances the look of the design element. There are two types of decorative overedge stitch formation. One is purl edge serging, which may be formed by 1 needle thread and 1 looper threads, or 1 needle thread and 2 looper threads, or by 1 needle thread and 2 looper threads forming a double pearl on the edge of the seam. The other variant could be an overedge stitch from 2 needle threads and 2 looper threads with the looper threads forming a purl on the edge of the seam. Here either there right needle only enters the upper looper loop or both needles enter the upper looper loop. The other type of overedge stitch formation is lettuce edge serging: the stitch formation is with reverse differential feeding action to uniformly stretch the fabric as it is being sewn.

The DK2500/3 from Titan is an ideal machine for the over-edging of multiple layers of mattress fabrics or other heavy materials. MG-2DNR-1 from Merrow is another ideal machine for making such kind of overedge.

Fagoting & Picoetta Stitch

Intended to attach two separate pieces of fabric creating drawn thread spacing, fagoting is a form of a decorative chain stitch innovatively incorporated on belts, collars, cuffs and sleeves, hemlines and as a design element on yokes. The recommended thread is T-24 PW Core or T- 27, T-30 Spun poly. Picoetta is a two thread Multi-Step Chainstitch used to topstitch a seam on women, infant and kids wear. The recommended thread for this stitch is T-24 PW Core or T-27 Spun Poly.

Advisable machine is 53400K from Juki, which is Multi-step zigzag, 1- or 2-needle picoetta and fagoting machine with differential feed and edge guide for decorative stitching.

Fly or Feather Stitch

Resembling the shape of a flying bird, the fly stitch and its variations are seen in garments, on hemlines, collars, cuffs and yokes. It is made up of ‘V’ shaped loops which are then tied down by a vertical straight stitch. Fly stitch is categorized within the feather stitches, which are open, looped stitches worked alternately to the right and left of a central rib. Other variations of this stitch include closed, open, whipped and reversed stitch. This stitch is most suitable for creating borders and quilting. The stitch best represents twigs and grass.

The Janome 712 T is an ideal machine for making feather stitch.

Fringing

Fringing is sewing a decorative border or edging of hanging threads, cords, or strips, on the carpets or bed linen. Fringes can either be made via a machine which stitches the hangings as the fabric moves below the needle or it can be an ornamental textile trim applied to an edge of an item. More commonly, it is made separately and sewn on, consisting sometimes of projecting ends, twisted or plaited together, and sometimes of loose threads of wool, silk, or linen, or narrow strips of leather. Fringing can be done on a variety of products like carpets, towels, drapery, epaulette, etc.

The Titan DK 3700F is an alternative for readymade fringes and Titan DK 3200 is a fast fringing machine for direct on fabric fringing.

Saddle Stitch

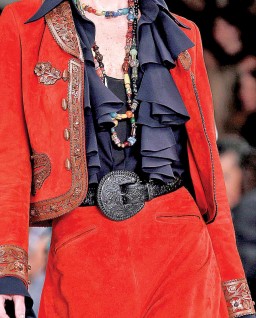

Widely seen as a decorative stitch in leather accessories to tailor belts, shoes and jackets, more than for decorative purpose, the saddle stitch strongly holds hems, collars, cuffs and pockets in apparels. The thread used for this stitch is usually in a contrasting colour to the fabric or surface to make it stand out; besides using a different coloured thread, a thicker or heavier thread may also be used to increase the visibility of the contrast stitching.

Saddle stitching is done similar to a running stitch. The needle is moved in and out along the stitching line, keeping a distance of about half an inch between two stitches. The length of a stitch should be the same as the distance between the stitches. In pin or saddle stitch there are two types – one with chain at the back and another hand Stitch look both at face and back. The first type is Single Thread Chain Stitch, formed when a needle carries a loop of thread through the fabric that is then picked up by a hook needle that brings the needle loop back to the topside. The distance between the needle and hook needle determines the length of the pin or saddle stitch. The length of the stitch varies from 1/16” to 7/32” or 1.5 mm to 5.5 mm. The pin or saddle stitch is actually formed on the underside of the seam as it is sewn, generally 2.5 to 5.5 stitches per inch. The stitch is mainly used in decorative topstitching of coats, jackets, dresses, etc.

The other type is Single Hand Stitch. It is formed when a double pointed needle with the eye in the centre carries an end of thread through the fabric. Seam is limited to 90 cm long. The recommended thread for both stitches is T-24 to T-60 PW Core or Spun Poly.

The MP-200NL from Juki, 781-X from Japsew, Artisan (USA) 880 is an efficient saddle stitching machine. The machine can be used for topstitching on the front facing of men’s wear, pocket mouths and trouser sides.

Another finishing stitch shaped similar to a shell, creatively used to scallop undefined and raw ends of the hem and cuffs, the shell stitch is made with an over edge machine with a special attachment that forms the thread around the edge of the fabric in a shell appearing configuration. Shell stitches take the shape of arcs and semicircles, hence the name. A standard shell stitch generally has 5 shells per inch with a standard stitch width of 5 mm. The stitch is ideal for serging women, girls, and infants clothing, a larger shell stitch can also be formed with a width of 9.5 to 12.7 mm with 2 shells per inch. It is used for the edge stitching on infant-wear outerwear or blankets. The recommended thread: T-21 – T-40 Spun Poly or PW Core for standard and T-40 to T-60 spun poly for large shell stitch.

Any overlock machine using an attachment from companies like Kwok Hing or Inderle. However, Merrow MG-3Q-3, J-38 from Japsew is standalone machines for the purpose of shell stitching.

Hemstitch is a decoratively drawn thread work or openwork hand-sewing technique for embellishing the hem of clothing or household linens. Ideally in hemstitching, one or more threads are drawn out of the fabric parallel and next to the turned hem, and stitches bundle the remaining threads in a variety of decorative patterns while securing the hem in place. Multiple rows of drawn thread work may be used. Industrial hemstitching machine has a piercer that pierces holes into the fabric and two separate needles that sew the hole open. This stitch is applicable in scarves, handkerchiefs, traditional table linen, bed linen, light curtains, etc.

Cornely 10-3 Picot hemstitch machine is ideal for making such stitches.